So, I'm late to this party. This ECU has been on the market for several years. It's been on my radar to try since it was introduced, but the opportunity just never presented itself. Well, we finally got the chance and it didn't disappoint.

We've been a big fan of the ECUMaster PMU power distribution modules and ADU display dash/logger for some time. I've always said my highest compliment is for a device to do what it says it will do every time. If a device doesn't live up to its' spec sheet or its' functions work inconsistently, we have problems. Doing what they say they'll do has always been my experience with the ECUMaster products and now I can say the same about the EMU Black.

We partnered with a local racer to help with his NB Miata track car and its' K24Z3 engine swap. He brought us a car devoid of any wire and we went nuts with the ECUMaster catalog. A PMU-16 provides power distribution, and ADU5 logger dash and GPS receiver handle the data. And we speced a Black ECU to do engine control. The K24Z3 has a variable centerline intake cam and VTEC on the exhaust cam. Not hugely complicated, but we would need good closed loop control of the intake cam and dual fuel and ignition mapping to cover the high and low side of the VTEC cam. ECUMaster has this covered.

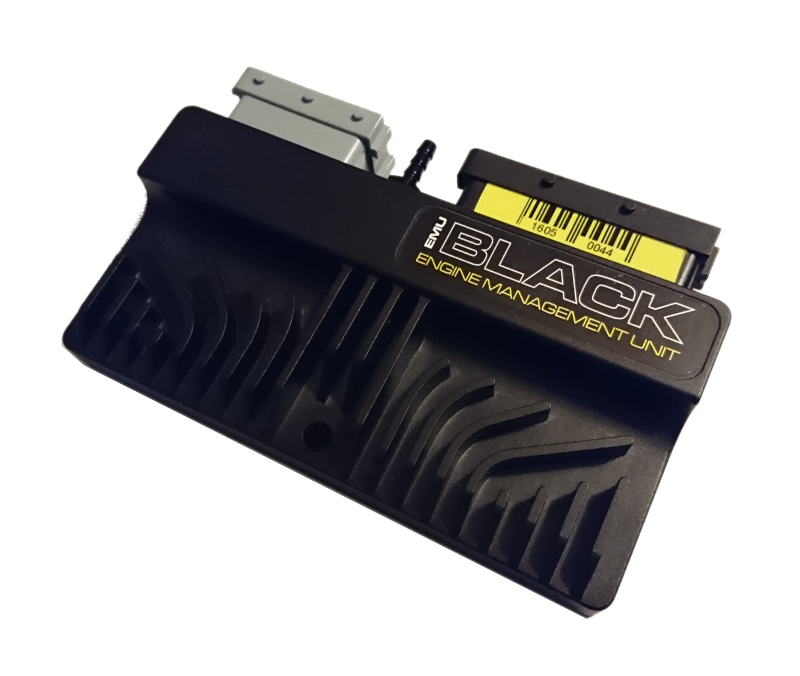

The basics of the Black are 8 injection drivers and 6 ignition drivers. The ECU can driver smart or dumb coils. No external ignition drive required for the those 2-wire coils. The ECU features an on board O2 controller that can accommodate a Bosch 4.2 or 4.9 sensor. The Black has DBW functionality, stepper control, and active knock control. One of the nicest features are 2 direct EGT connections. No need for an external amplifier. Perfect for those 2 rotor setups. I also love having this option for turbo compressor outlet temp measurement. In short, it's a full featured box with a lot going for it. Much more so for the list price of $1099!

The Black, and the entire ECUMaster line, employs user defined CAN bus programming that allow their products to easily interface with each other and products from other manufacturers.

The software is my one complaint. It works well enough. It's just a bit cumbersome, in my opinion. The functionality is pretty good compared to other popular systems. But the layout is disjointed and lacks some of the customizable features available with some of the better GUIs on the market.

Datalogging is pretty good. The Black will log to a laptop only. It does not have on board logging capability. ECUMaster offers a separate logger module. In our case, the ECU is paired with the ADU logger dash which can generate large, high resolution logs while on track. In a dyno setting, the PC logging works well and is real time. It doesn't require a log to be downloaded or processed after a run to be viewed. It's just there is chart screen. All channels are logged simultaneously, so there's practically all the data you'll need in each log with little need to setup what is logged before hand. The one exception to the this is the PID debug parameters. For some reason you're only capable of logging one PID parameter for each individual P, I, and D response. So you have to choose from VVT, boost control, idle, etc., before you generate the log. Not a huge deal but you wouldn't be able to see VVT and boost PID in the same log. Just one of them and a simple overall duty cycle for all others. Also, there is no ability to do math functions on the data after it's been generated. I wanted to look at wheel speed versus engine RPM to verify clutch slip. A very basic math function would take all the guess work out of this. Math functions would be a nice addition. If you do want to do advanced data analysis, you can always export the logs in xls format to your favorite analysis program.

The ECU and GUI have a nice trigger scope function. It's not a true scope, in that it only shows trigger edges and doesn't actually show wave peaks and valleys. What it does show is each edge of crank and up to 2 cam sensors and how they relate to each other. This allowed us to sort the K24Z3 60-2 crank, 3 uneven tooth cam, and 4 even tooth cam trigger without a base map or the need to call tech support. We used the scope function and followed the documentation and help files included in the software. Very good feature.

Speaking of PID, the idle and VVT control functions worked very well on our project. PID configuration can be very frustrating. In my experience, some systems are just easier to configure and more responsive. The Black worked well and was pretty straight forward to configure.

Fuel map auto tuning is an available feature. It works best with a dyno with load control. We used this function when we mapped the K24 and it worked very well. Essentially you engage the function and then just drive the car on the dyno and allow it to hit all the cells you want to calibrate. You'll need to hold the engine steady in each cell for several seconds while the ECU compares actual Lambda to the target and then applies the change. It's a similar function to that offered by other manufacturers and works very well.

In the end, we're happy to say the Black, like the other ECUMaster products we've used, do what they say they will. We're looking forward to using them on more projects and excited about the recently released full rotary engine support with OMP functionality.